Robot Damshii ELS QAN[T] posed in the style of Gundam 00 movie ending scene. Image from Yui's blog

After part 1 and part 2, the final part for TAMASHII Feature's Vol. 7 coverage is on the making of a Robot Damashii action figure. I find this to be rather interesting as it's not something that is featured often, so I dedicated a post for it.

1. A conference is held with several departments to discuss what to be merchandised, the release date, and other proposals.

2. Once the proposal is determined, the license holder of the subject is contacted for permission of merchandising.

As the example here is Robot Damashii Full Armour Unicorn Gundam, Tamashii Nation will seek Sunrise for permission.

Every samples progress will be co-supervised by the license holder

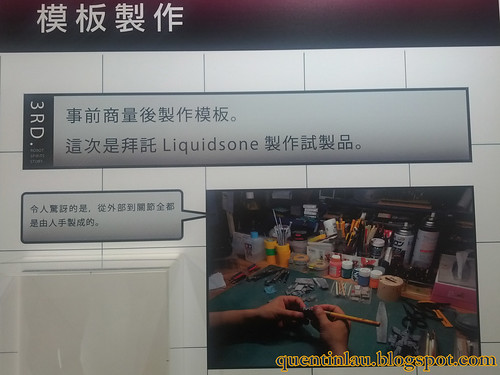

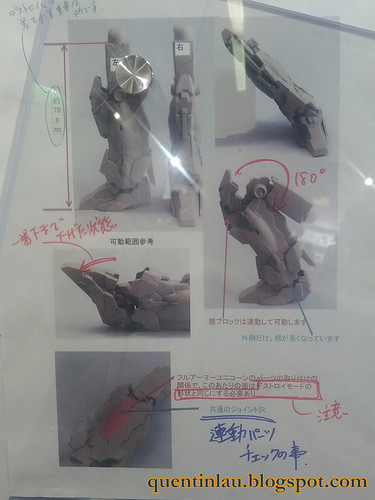

3. After getting permission, a sculpted sample is to be made by a company called Liquidsone. All parts, including the joints, are done by hand.

Liquidsone is apparently a company that specialises on sculpting samples of action figures, be it for mechs or for bishoujo characters. What's strange is that I can't find any info for it online, unless the name is misspelt, which would be rather embarassing (I hope this is not the case!).

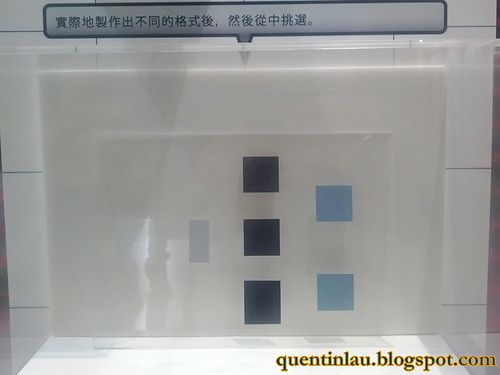

4. Once the sample is sculpted, colouring comes next. Since the Full Armour Unicorn Gundam is based on previous previous releases of Unicorn Gundam, the colour of the actual Gundam is already decided. Just the extra weapons need further decision after comparing with the colours used in the anime.

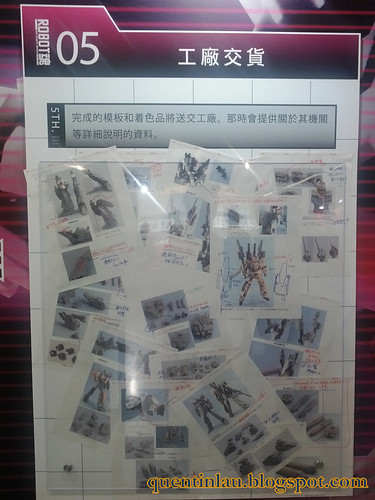

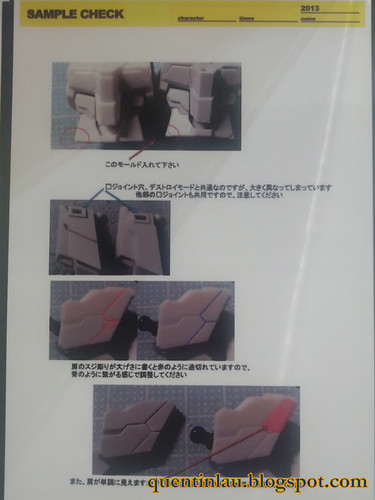

5. The coloured sample is sent to the factory together with instructions and any further specifications.

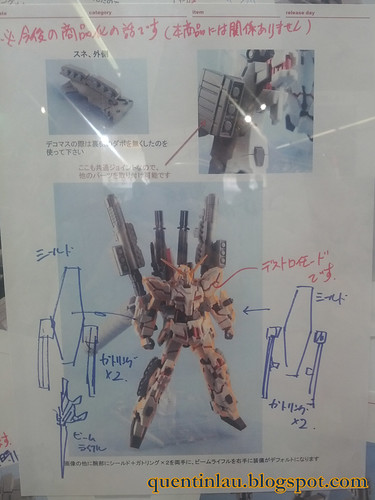

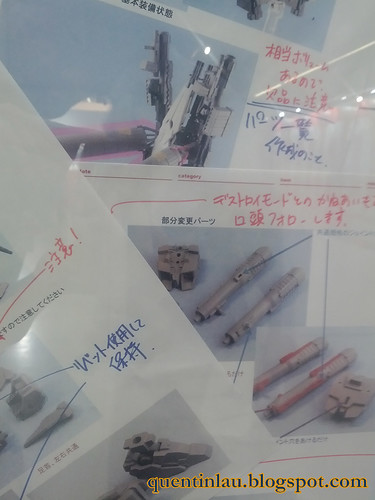

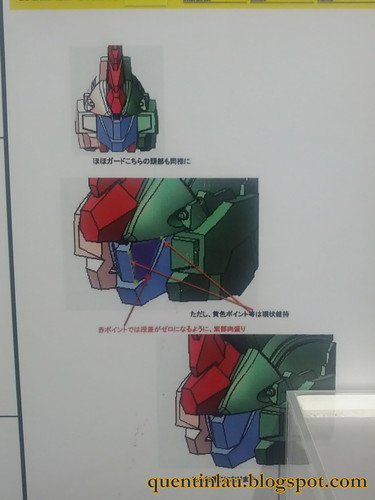

Specific instructions, such as which parts are the same from older releases, which parts share the same pegs / hole sizes, and articulations are annotated across various pictures for the factory to understand and make a factory sample.

6. Sample revision. Factory's sample is not perfect on the first time for replication of the sculptor's sample. It takes multiple revisions before a final sample is approved by Bandai for mass production.

7. Photo shooting. Once sample is finalised, it is taken for photo shooting. The joints for the sample are not as stiff as the final product, therefore it can take much more time to pose and keep it in place while taking photos.

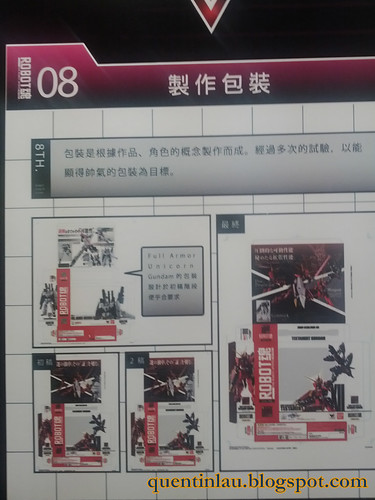

8. Package design. The idea for the package design is to look cool. The picture above shows how the package layout for Testament Gundam is based on Full Armour Unicorn.

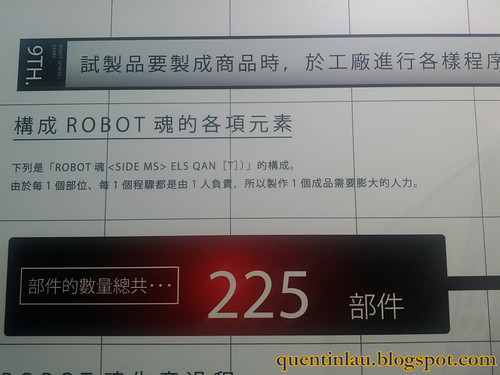

9. Mass Production. Mass producing the final product based on the final approved factory sample takes quite a few steps as seen in the picture above. I'll break it down into smaller sections for explanation.

We take ELS QAN[T] for example, which was a web shop limited item released at the end of last year. According to them, each part and each step is carried out by one person, therefore making one full product requires a lot of manpower.

Robot Damashii ELS QAN[T] has a total of 225 parts (!).

A total of 177 steps is required for colouring, and the total number of people responsible for mass producing is approximately 400 people (!). ELS QAN[T] has a lot of colour gradation, therefore it is antitipcated to need a lot of colouring.

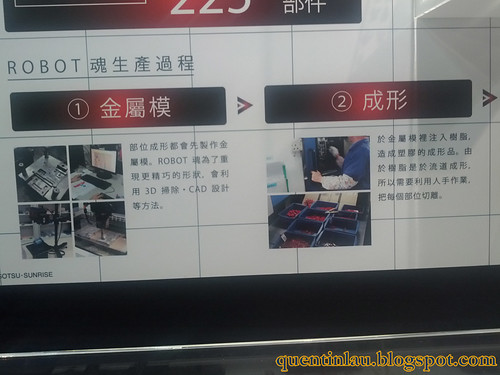

What about from the beginning? First the metal mould must be made for the parts. For precision in replication 3D scanning and CAD are used. Once the moulds are made, plastic is hot injected into the mould, forming runners, and the parts have to be cut away by hand.

The parts are then painted before being assembled.

Here are the moulds that were on display. All are made of metal, and all have a slot where plastic is injected into the mould to form the runners.

And here are the runners formed after the moulds are removed. They look like those seen in model kits, don't they? The main difference between those in mass production and those for model kits is that the former has minimal runners for efficiency; the latter tend to have a full frame around as seen in Gunpla kits.

Masks are used for holding specific parts in placed, while revealing only the required area for painting. Each are unique for their own corresponding parts, just like the moulds.

For very fine details, decals are used instead.

And here is the final product. 225 parts in one package done by 400+ people.

It's an interesting insight to see how the toys are made from planning to mass production. Many toys are more or less manufactured in the same way, but it's nice to see some of the backstage work that contribute to the final product we get at the end. Next time you get a Robot Damashii, or any other toys, think about the efforts behind it!

That is freaking a lot of parts and truly a time consuming process. I am so glad you shared this as it really speaks volumes in the process and final product.

ReplyDeleteDespite having seen videos and moulds in previous events before, this is the first time I really get to know the numbers behind the making, as well as the getting to see drafts and annotations on how to improve the samples. I quite like that being showed in the event!

Delete